Maintenance

A data center is part of an organization’s IT infrastructure where they store mission-critical data and applications. To ensure it’s functioning to its maximum efficiency, regular data center maintenance checks are essential. Data center maintenance involves keeping the data center components and the environment in a good state of repair and physical health. Meaning, keeping the data center hardware equipment, building facility, and hosted equipment functional and operational.

Regular data center maintenance is a crucial part of a data center’s operations. It’s essential for improving data center design and enhancing an organization’s IT infrastructure.

At IDCS, we stand behind our data center design and construction. Our unwavering commitment to integrity is reflected in how we approach your data center service and maintenance. Our extensive data center expertise allows us to match your business needs with the best service and maintenance in the industry.

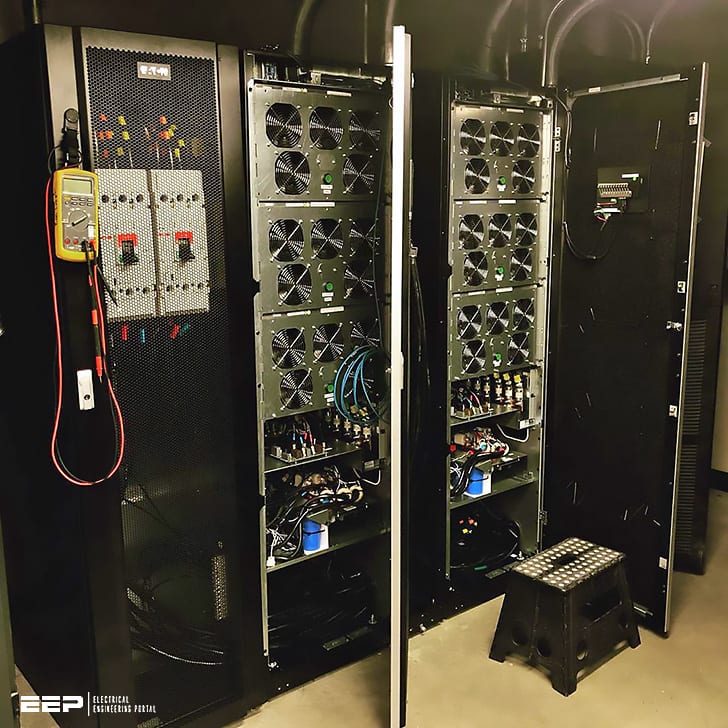

UPS Maintenance

The Uninterruptible Power System (UPS) is the electrical power path to business critical loads, making UPS Maintenance – critical. The primary purpose of the UPS Maintenance inspection is to be proactive by ensuring that the UPS, Batteries, and Peripheral components are operating within specifications, all components are in good order and the system will be available to support its critical load, period.

IDCS will provide complete and detailed inspections. With both our qualified engineers and our other nationwide service partners, we are capable of offering highly responsive and timely repairs and maintenance on most major manufacturers equipment on a nationwide basis.

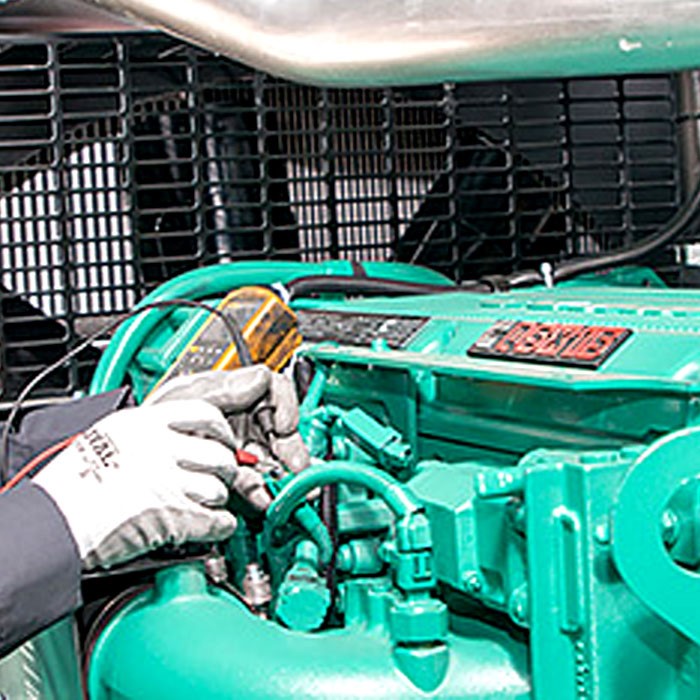

Generator Maintenance

Diesel generator sets – used for either prime or backup (emergency) power – must be regularly maintained to ensure they provide quality power throughout their service life. The failure of a single power source can cripple entire operations in seconds, resulting in massive delays and partial or complete shutdowns.

Some components of generator maintenance require weekly or monthly checks depending on generator operation hours. This includes checking fuel and coolant levels. Other types of maintenance can be done on a bi-annual and annual basis such as checking electrical wiring and battery cables and connections as well as changing fuel and air filters.

Backup Battery Maintenance

Batteries are the lifeblood of your UPS or telecommunications system, the power source for your standby generators and may provide backup power for your switchgear. In the event of a power emergency, batteries will provide continued operation of your computer, voice and data communications systems – but only if they work.

Failure to properly maintain your batteries or carry out regular checks can result in surprise failures in the battery when it is called upon to support the load. The key to ensuring the reliable operation of your battery backup is a comprehensive predictive maintenance and testing program.

PAC Maintenance

A precision air conditioning (PAC) unit is a device that monitors and maintains the temperature, air distribution and humidity in a computer room or data center. The failure of a PAC unit can lead to downtime, which of course means a loss of service and that can translate into a loss of money and often times a loss of customers.

To maximize the efficiency and maintain the consistency of your precision air conditioning, it is important to develop and stick to a long term service plan that includes preventive maintenance and optimization of the precision cooling system.

Our engineering approach is comprehensive and ensures a full assessment of the air conditioning unit(s) on site, including both indoor and outdoor units, pipework and electrical circuits.

Fire Protection System Maintenance

A fire protection system is one of the most critical aspects of your facility’s infrastructure. Inspection and maintenance services ensure that your fire protection system will operate properly when you need it most. Regular, periodic inspection and testing is the best defense against system failure so that you may continue to operate your business securely and efficiently.

Tests are performed by operating each component of the system to assure it performs as required in the case of an actual emergency event. Many components in a fire protection system will require preventative maintenance at a prescribed frequency. These maintenance activities address components that degrade over time, have a finite lifespan or require periodic resetting or calibration.

CCTV System Maintenance

Closed-circuit television system or CCTV systems maintenance is a preventive measure to ensure that surveillance equipment is operational. CCTV maintenance is an integral part of any organization’s security strategy and timely, thorough maintenance is the only way you can ensure your CCTV security system is keeping your facility and your employees safe from intruders, criminals, and vandals.

Our CCTV systems maintenance services and repair are provided for all types of CCTV and DVR systems. Our highly qualified team of engineers can perform annual checks on your system to give you complete peace of mind that your chosen system is working at its best.

Access Control System Maintenance

An access control system needs that operates constantly will ensure that only valid and authorized areas are accessed, by authorized people with the correct credentials.

In order to continue to protect people, property and processes, your access control system needs to remain working to its optimum capability. Regular routine inspections helps identify vulnerabilities, fix minor problems and safeguard against major breakdowns.

We offer preventative maintenance packages helping to prolong the life of your access control systems, to ensure your system’s performance and to give you complete peace of mind that your access control is working effectively.

Water Detection System Maintenance

Water detection system is commonly installed in data centers, communications rooms and other information technology dependent structures. Leaking water from HVAC, AC units, water pipes, drainage or even ground water can cause significant disruption.

Water detection systems are not maintenance free, regular servicing is essential to ensure leak detection system are operating correctly. In general systems will need to be inspected every 3 or 6 months dependent on the system installed and the environment it’s been installed in. Alongside general wear and tear, there are a number of avoidable external factors that can impede their performance at the very moment they are required to act to protect your assets.

We are on hand to discuss your specific requirements

We are here to talk 9:00AM to 6:00PM, Monday to Friday